![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/6/csm_imos-Referenz-Schurig-Werkstatt-und-Buero_fe1e5293c2.jpg)

A perfect symbiosis of excellent handcraft and efficient digitization.

On 3.000 square meters, the company with 25 skilled employees manufactures everything from individual furniture to high-quality kitchens and store fittings to trade fair and event construction. Architects and interior designers all over the world are among the customers, among others in Paris, Moscow, New York, Los Angeles, Dubai and Shanghai. Not only the quality of the products plays a role. The quality of the cooperation is also crucial. And with often thousands of kilometers separating the joinery from customers, there is only one recipe for success: consistent digitization.

- Showrooms

- Office

- Fairs/Events

- Living

The carpentry 4.0

"We've never been on a construction site before," Klaus Schurig says with surprise. "I have never met the architects with whom I plan the projects in person. We communicate exclusively digitally. From measurements to designs, even with tricky details, to installation information, we exchange everything digitally in no time at all. Otherwise, we wouldn't be able to handle international projects at all. In many companies, it's just a matter of getting design data onto the machine. But in terms of our international business connections, we would be nowhere near competitive on that alone."

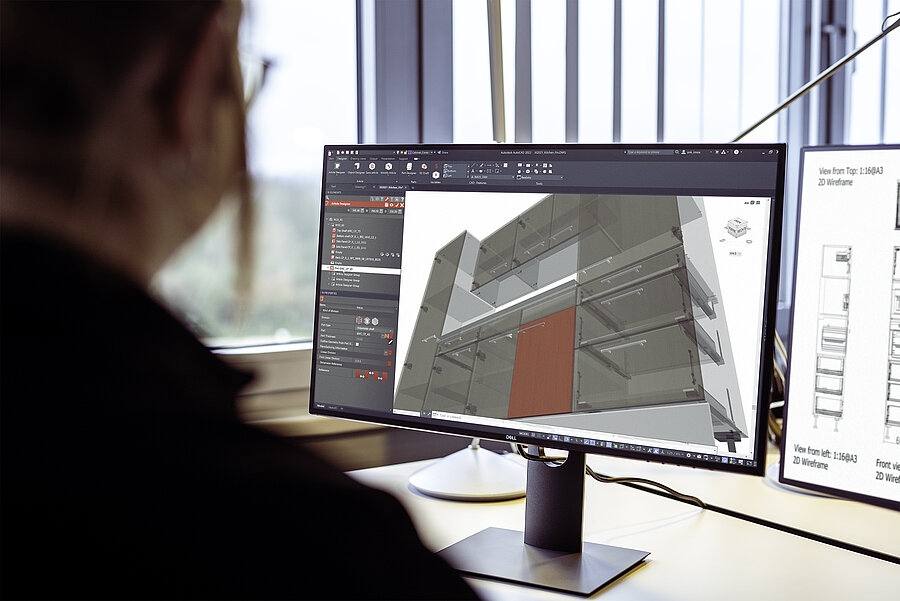

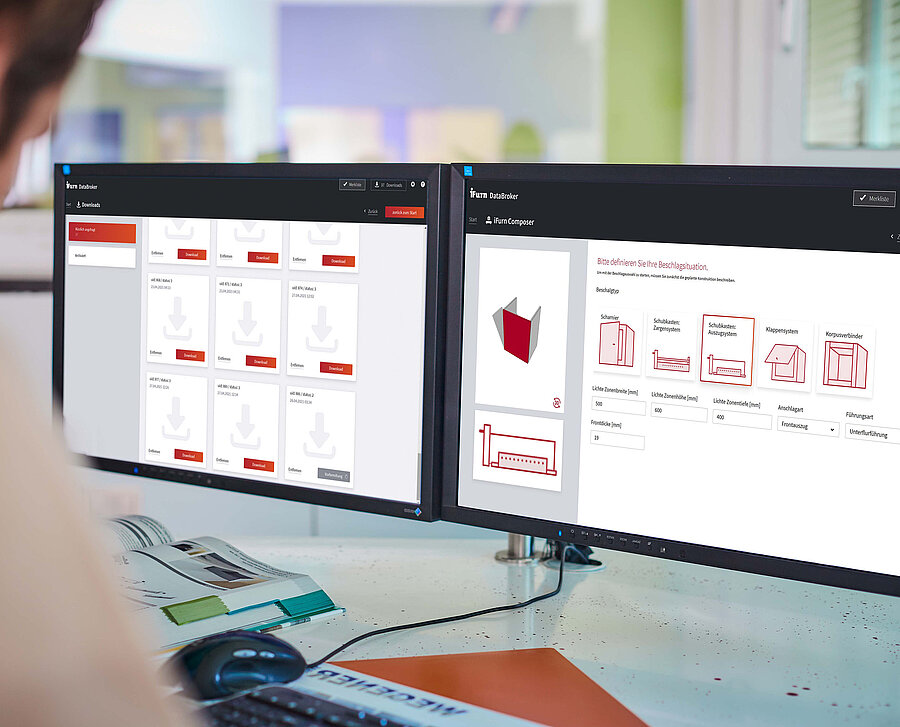

For several years now, Schurig has been practicing complete digital networking, both internally and externally in cooperation with suppliers and customers. Measurement system, design with imos iX, supplemented by iFurn for fittings and suppliers, CNC cutting, commercial data, transfer to ERP programs. There, the data is further processed into parts lists, lists for material requirements or purchasing lists. The employee in the carpenter's workshop receives all data in the work preparation and puts it down as an order for the entire company, including the commercial order processing.

When we introduced imos iX in 2013, everyone said you would need six months to three quarters of a year to be able to manufacture. We produced the first furniture after just four weeks. The connection of different areas based on the imos iX database from CAD to the machine works perfectly.