Automated order processes with the Integration Server

This is how order processes run by themselves - and in the background

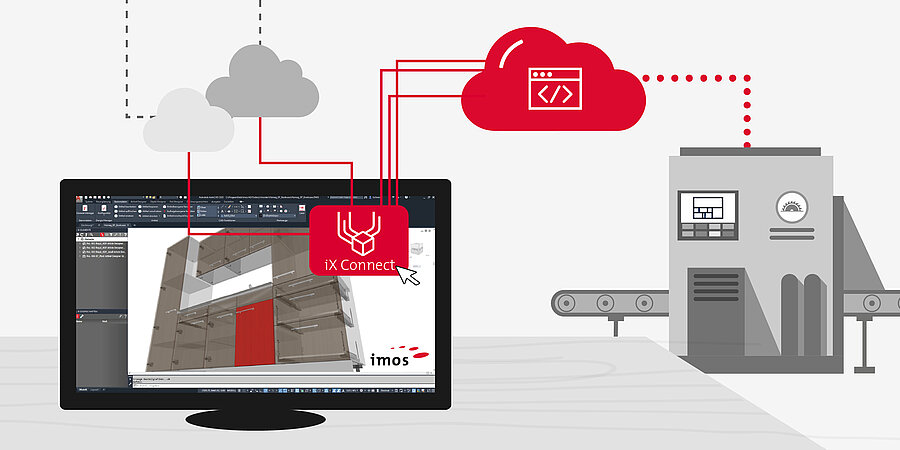

The Integration Server is a central tool with which users can professionally connect their imos iX world with external systems such as ERP, MES or sales systems.

The generation of data or the import of orders are always consistent in terms of the process, but take up quite a bit of time and computing power. By automating their order processes and the final production data generation to a large extent, users can concentrate on the essentials in order processing - the Integration Server takes care of these tasks in the background and on another system so that work can continue undisturbed and without waiting time. The result is complete and technically flawless data for the entire order and production process.

Highlights at a glance

- Process Automation Services

- Process monitoring

- Error Logging

- Cross-system data exchange

- Execution of multi-processes

- Numerous interfaces to ERP, MES and industry solutions

- Scalability of the system

- Individual system configuration

- Central system administration (multi-client environment)

- Central process control/load distribution

Application areas and functions of the Integration Server

Intelligent software agents - so-called iBots - are assembled into interface apps and then independently handle the exchange of data between different applications such as ERP, MES and POS with the Integration Server. Error logging and monitoring bring the necessary transparency to the data flow and help with error analysis.

In conjunction with the iX NET, iX PLAN or iX Organizer software modules, users can enter orders decentrally at the end customer or in the showroom and finally load them into iX CAD in the form of an order. Due to the use of the same data in the different applications, security and consistency is guaranteed throughout the entire process.

Users can import order data from iX NET Shops as well as return the order status to the store.

Not only can order data and master data be imported, but optionally a subsequent action can be initiated for the orders.

Via an order file in XML format, users create a complete order with articles from the catalog and variable values. The order file can be specified by any system.

All output functions can be edited via the Integration Server.

Order header data and associated actions such as creating, updating, or archiving are communicated between imos iX and the ERP to enable cross-system synchronicity.

Production information is used to determine how orders are to be divided into individual production orders. The process can be linked to other processes.

Special facts about the Integration Server

Automated data exchange

The Integration Server is a framework for automating order management and process data generation using configurable "iBots". iBots are atomic integration modules that can be assembled into molecular connectors. They organize and automate the exchange of data between different program modules and systems.

- Transparency and error analysis in the data flow thanks to error logging and monitoring

- Routine tasks such as exports/imports or the generation of outputs take place in the background (ideally overnight),

- No interaction with the user necessary

- No waiting for completion

- Output of corresponding logs for later analysis

Central system administration

The Integration Server application can be run on multiple clients (computers/machines), e.g. to achieve more computing power. The Integration Server interface is the same for all systems and administration is possible from any location, provided there is a connection to the SQL server.

- Simplified administration

- Good transparency

- No additional setup effort

- Easy to transfer to existing environment

Central process control

Processes are managed and monitored by a central instance. This increases the security of processes, especially in more complex system environments.

- Improved process security

- In case of failure of the active client, the tasks are automatically taken over by another client

- Implementation in existing system environments works automatically with the update

Execution of multi-processes

Various processes can be automated via the Integration Server. All configured processes, executed by the iBots, run in parallel and can be processed side by side.

- High time efficiency

- Utilization of the available computing power

Data security

Due to the use of the same data in the different applications, security and consistency is ensured throughout the process.

Individual system configuration

The Integration Server offers the possibility of configuration for all important elements, so that there is a suitable solution for almost all system environments.

Scalability of the system

The Integration Server can be implemented in different system sizes and is easily scalable. Scalability is implemented by adding or removing clients to adjust the necessary computing power.

- Adding another client is possible with very little effort. This is immediately a part of the existing system.

- Clients in the network do not have to be permanently active and can be used for something else in the meantime.

Process monitoring

The actions performed by Integration Server are transparent and listed in the logging.

Expand your possibilities in the production process!

These imos iX products are a useful addition to the Integration Server and make your processes even more efficient.

![[Translate to English:] Topfscharnier mit digitalem Zwilling](/fileadmin/_processed_/a/6/csm_digitaler-Zwilling-Topfscharnier_005aba55dd.jpg)

![[Translate to English:]](/fileadmin/_processed_/9/1/csm_imos-Homepage-Referenzen-Peter-Hay-Kitchens-Horizon-Apartments-1_4819f32ab7.jpg)