Automated CNC programming with iX CAM

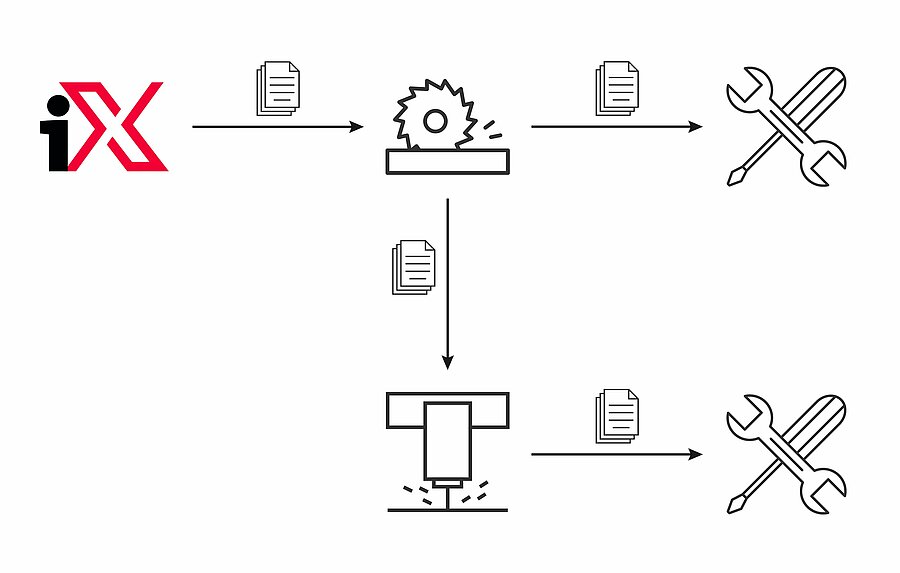

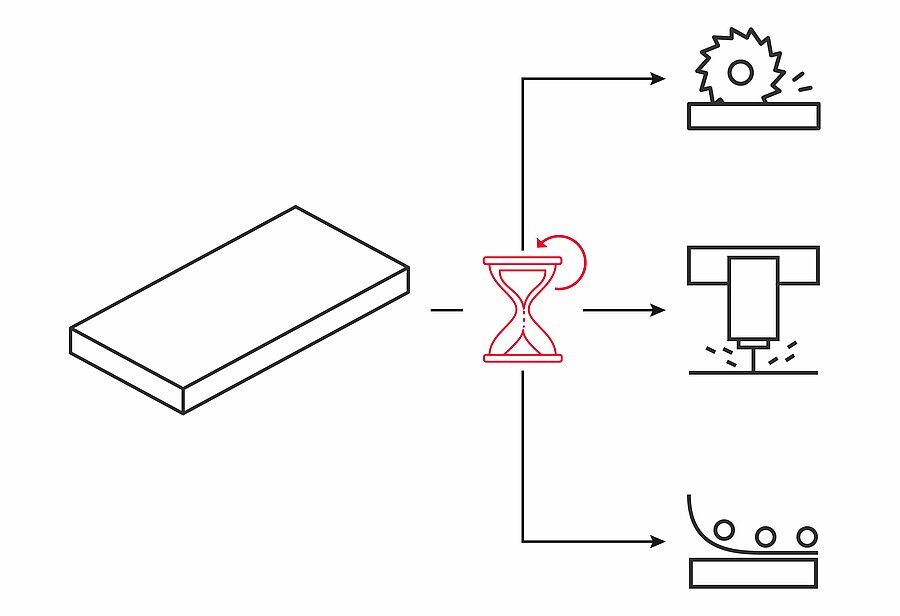

From planning or design directly to the machine.

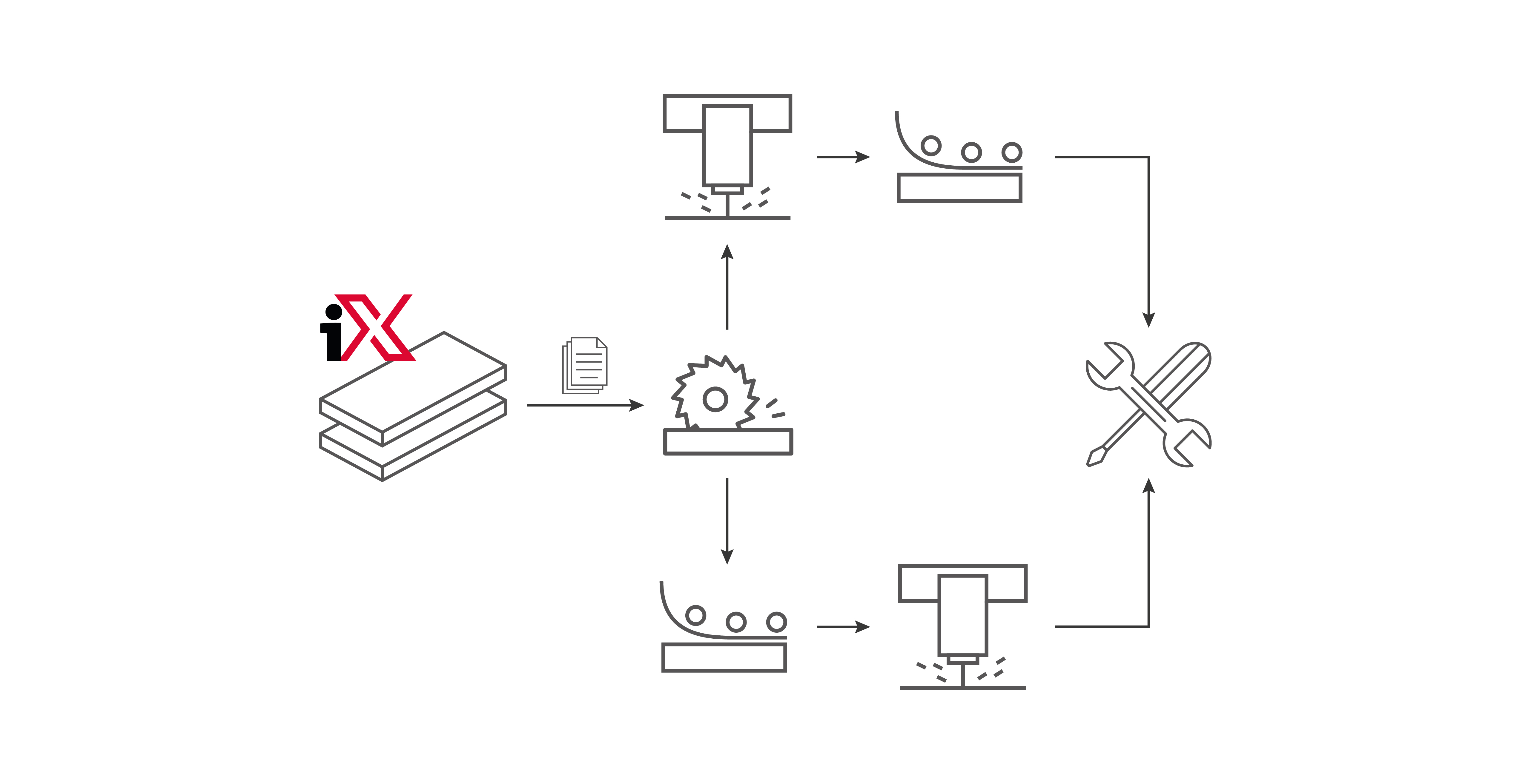

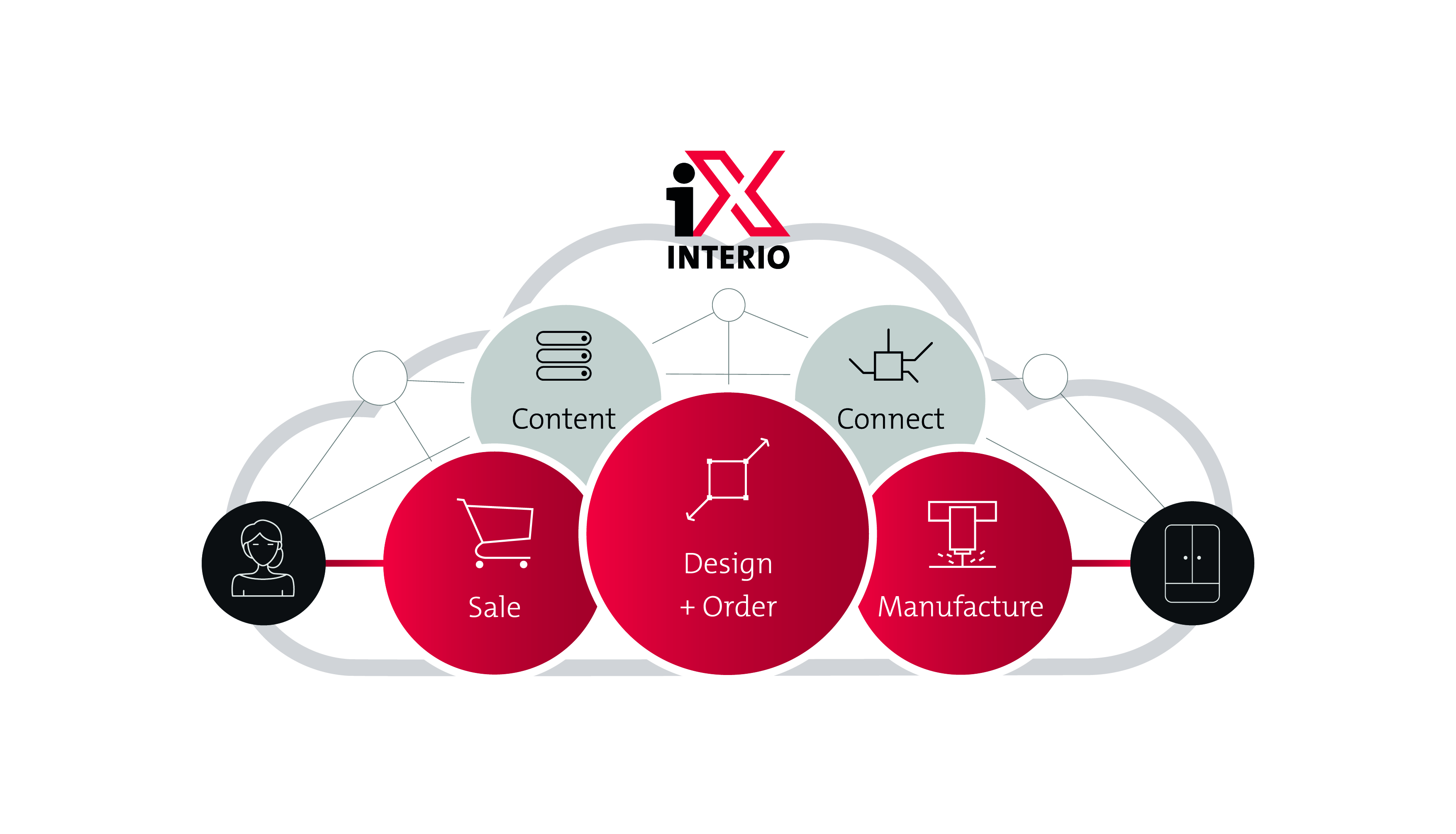

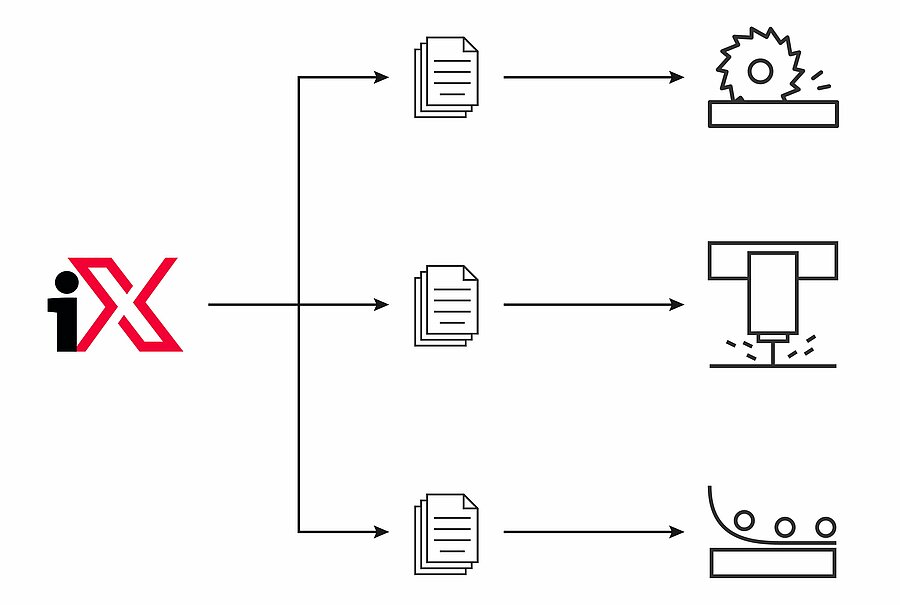

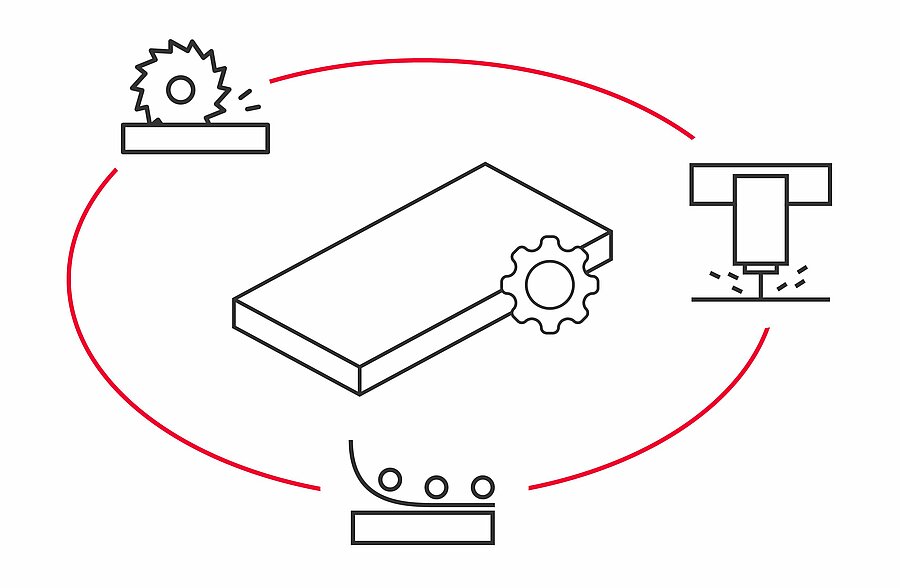

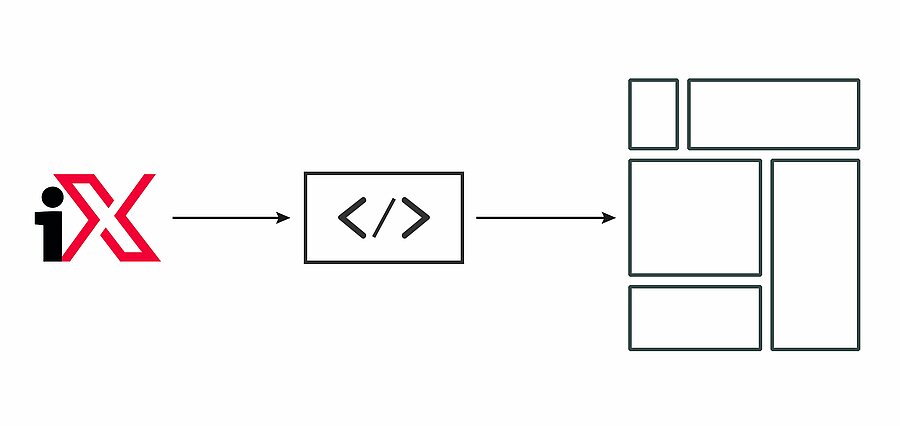

From the finished design drawing or the online store directly to the machine: iX CAM automatically generates the CNC programs for all common machine manufacturers from the planning or design - from the individual CNC machine to the workshop cell or the networked production plant. In addition, in-house production processes can be mapped and CNC data generation can be adapted to the respective production flow - simply, quickly, reliably and economically.

Even more functions for iX CAM

iX CAM can do even more - the range of functions can be easily extended with these optional add-ons:

Edge

With the add-on for edge gluing, the gluing processes of different machine manufacturers can be defined and controlled. While the process for HOMAG machines is defined in iX CAM, predefined macros are controlled for Biesse and SCM. For IMA machines, the IMA Quicktool is controlled and supplied with parameters.

Sandwich

The sandwich enables the generation of CNC programs for combined components (e.g. side panels with rows of holes) that can be clamped simultaneously on one machine. The programs of the individual components as well as the combined sandwich program with machining from above and below are created. The function is integrated as a call in the workflow. This makes it possible to define precisely which components are to be combined.

Multi Workflow

Multi Workflow allows the use of several CNC machines in one workflow, with different aggregate placement and postprocessors if necessary. In addition, the function "Process all matching workflows" is available. Previously, each part was assigned to a single matching workflow in the automatic CAM run. By activating this option, data from all matching workflows is written for each part. A downstream process can then use the data to optimize the utilization of all machines, e.g. in the event of a machine failure.

CAM Edit

With the help of iX CAM Edit, users animate and modify their process data while still processing the job, without changing their master data. This saves them a trip to the machine and additional software licenses. In the iXplorer tab of the same name, they will find the element tree with all generated programs. The context menu contains the options for isolating and visualizing programs and machining operations. A machining is selected to view and adjust its program values in the properties palette.

iX CAM at a glance

- Integrated in iX Organizer and iX CAD

- Production lists and NC data at the push of a button directly from iX CAD

- Direct connection of CNC machines and production lines of the most common brands

- Automated tool assignment

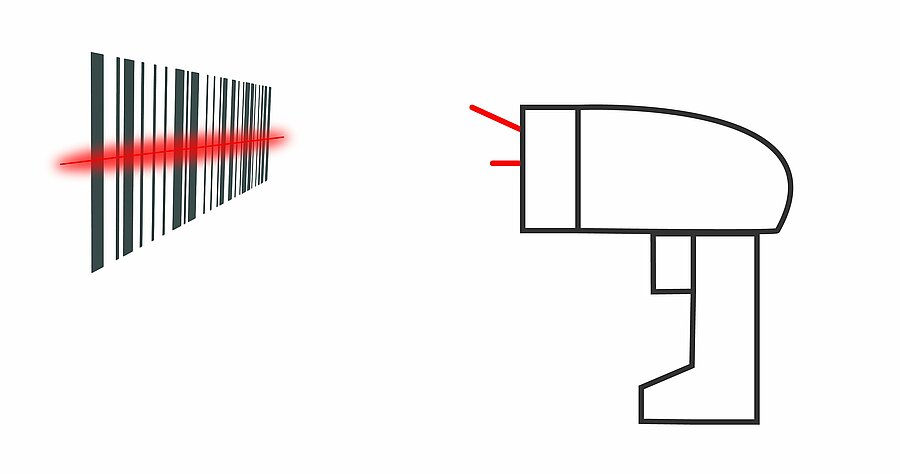

- Unique part identification by barcode labels

- Generation of approach and retract movements of the tool as well as automatic individual positioning of the parts

- Provision of nesting data to third-party systems

- Toolpath animation of the CNC programs in iX CAD

- Connection to manufacturer systems, including woodWOP, B-Solid and Maestro

- Connection of common cutting optimization software, e.g. Schnitt Profi(t), ARDIS, HPO, OptiPlanning, Ottimo

- Allocation of part machining to several machines

- Management of tools, technologies and machining strategies

- Special machining strategies for solid wood machining and edge banding on the CNC machine

- Calculation of machining times

![[Translate to English:]](/fileadmin/_processed_/1/6/csm_imos-Referenz-Schurig-Werkstatt-und-Buero_3b71b2ae5f.jpg)

![[Translate to English:]](/fileadmin/_processed_/9/d/csm_imos-Referenz-Hawk-Furniture-Buero-Moebel-2_bbc95f5fad.jpg)

![[Translate to English:]](/fileadmin/_processed_/9/1/csm_imos-Homepage-Referenzen-Peter-Hay-Kitchens-Horizon-Apartments-1_4819f32ab7.jpg)

![[Translate to English:]](/fileadmin/_processed_/5/9/csm_imos-Referenz-Hoso-Industry-Wohnraum-202105_022_08f8674bc7.jpeg)

![[Translate to English:]](/fileadmin/_processed_/a/1/csm_imos-Referenz-TUK-Tischlerei-Kleindienst-an-Maschine_94913d3abf.jpg)