Increased productivity from design to manufacturing

Peter Hay has made a name for itself with stylish kitchens that combine form and function. The company has taken the European design model and applied it to New Zealand's more individual design requirements with great success. Peter Hay is now the largest kitchen manufacturer in New Zealand, able to take on a wide range of projects, from one-off custom designs to large-scale projects. Peter Hay manufactures a full range of residential kitchens at its facility in Manukau, Auckland. The company offers a complete design, manufacturing and installation process, with everything done in-house. Complete control over the entire process enhances communication between the customer and the company.

- Kitchens

- Household cabinets

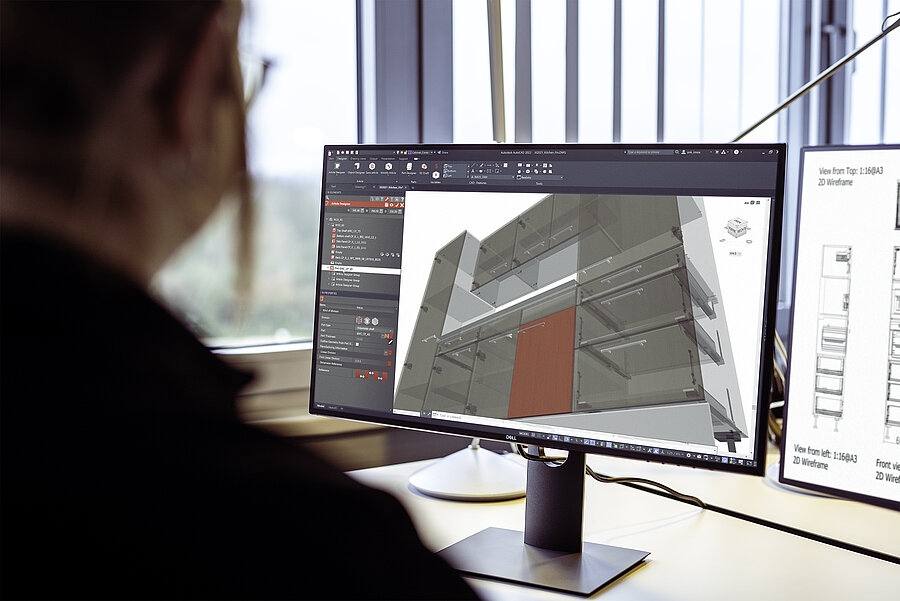

Connecting the showroom to manufacturing with imos is key to our business success. Designers using iX PLAN can create rendered drawings for presentation from a specially created catalog. Production planners take those same drawings, create cut lists, and convert them to CNC files for manufacturing with ease and speed. This has streamlined the entire process from start to finish.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/c/csm_P-Hay-Kitchens-9271-min-scaled-e1645693871171_1c860a66ee.jpeg)

The company offers a fully functional 300-square-meter showroom at its Manukau manufacturing facility, providing the perfect platform from which customers can realize their dreams and view the latest trends and products. This is complemented by an urban showroom at the Home Ideas Centre in Parnell, providing customers with a central showroom in the city seven days a week. Continued investment in new technology has enabled Peter Hay to stay at the forefront of the latest manufacturing and design trends. A recent example is the imos design and manufacturing software.

imos has also made it easy to add new products to the existing library. With an ever-growing customer base and product range, this has also accelerated the overall product development process. imos provides us with an accurate breakdown of material and manufacturing costs. In the future, we plan to optimize more imos modules. This would allow us to manage inventory versus made to order items and forecast planned projects.

![[Translate to English:]](/fileadmin/_processed_/b/8/csm_Frau-an-Laptop-Frontperspektive-unsplash_700df986f5.jpg)