More insight, fewer mistakes: iX Scout provides support in complex projects of individual store fitting

Borchardt Ladenbau specializes in the individual interior design of bakeries, butcher shops and restaurants. Wherever conventional cabinets are not an option, the company has made a name for itself among customers and architects for highly complex counter developments. In addition to slopes and curves, different materials such as glass and metal as well as a lot of technology for electrical and built-in elements or aggregates have to be installed.

- Shopfitting for bakeries, butcher stores and the catering industry

Borchardt Ladenbau is one of the first imos users who employs iX Scout. The digital order assistant supports the team in all phases of a project – with great success.

A smooth flow in shopfitting

By accessing the video, you agree to our privacy policy and consent to your data being transmitted to YouTube.

Upload to the cloud instead of thick project folders in production engineering process

"Already in production engineering process, iX Scout saves us a lot of time and a lot of work," says Andreas Borchardt as the company's technical manager. "We used to create thick folders for each project and print out a multitude of plans and documents. Today, it's just a mouse click to upload all documents to the cloud - and they're available immediately, wherever they're needed in the business."

Almost no misproductions in manufacturing

This is also a clear advantage for Andreas Borchardt: "An average order for us comprises around 300 to 500 components. The problem in the past, especially when we produced parts for multiple orders, was that some parts could not be clearly assigned to the orders and were produced incorrectly because the identification was missing. Then they were incorrectly placed on our CNC processing machines or the edge banding – and later in assembly it didn't fit and we had to produce again."

"Today, every part on the panel saw is tagged with a QR code. A scan with iX Scout is sufficient, the employee is immediately informed about the affiliation and installation situation and can take this into account during processing. Since then, faulty production has been virtually eliminated."

Overview and attention to detail in pre-assembly

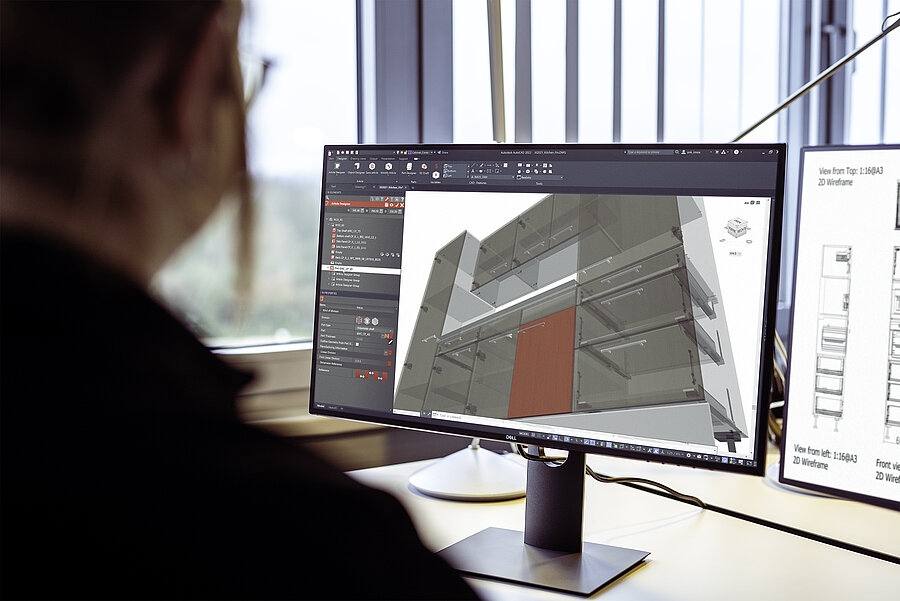

In the 3D view, employees can not only view the order model, but also interactively explore individual objects. With the intuitive navigation, they quickly find their way around. Individual elements can be selected with a tap or click, dimensions and all other properties as well as the associated chat history are displayed. It is this attention to detail that is also convincing at Borchardt.

"In our pre-assembly department, even large-format printouts of plans used to be confusing. A multitude of colored lines overlapped and details were hardly recognizable. In iX Scout, components or groups can be easily hidden or highlighted in color. Using the zoom function, we can even make every hole visible and get all the information, for example, which fitting has to be used on which part."

Uncomplicated communication on the construction site – and always all documents at hand

"We like to use the chat function on the construction site," explains Andreas Borchardt. "There are always surprises during installation. Sometimes the measurements are not one hundred percent correct, sometimes other trades have laid pipes or lines that deviate from our plans, and rarely a part is damaged, for example during transport. Then we have to react quickly.

If something can't be repaired on site, we send it directly to the workshop. Using the 3D data, we can clearly mark parts and positions and provide them with instructions. Seconds later, our colleagues know what's going on and can start production again or make the necessary changes. That saves considerable time and gives us security."

Another advantage of iX Scout is the completeness of the information that is now available to the team on the construction site. In the past, if something was missing, it was immensely time-consuming to obtain plans or documents, because Borchardt works throughout Germany.

The fitters use iX Scout to call up comprehensive assembly instructions, for example. At a glance, it is clear which components belong where and how they must be mounted. Fittings can not only be called up via the list, the preview also shows the exact installation location in the construction.

Implement change requests easily – errors excluded

There is also another advantage that has eliminated a known potential for error. "In the ongoing order process, there are always change requests from time to time. In the past, we then had to print out new plans and inform colleagues verbally. At that time, the project folders comprised several 100 pages, which at some point represented an unacceptable flood of paper. Especially when individual things had to be updated and certain plans had to be replaced."

In principle, iX Scout pays for itself by eliminating sources of error. I can precisely track every part that is manufactured in our production until it is completely finished and delivered. And every employee at every workstation is able to see exactly where this component is installed. This is a fundamental advantage when many special features have to be taken into account. And that's the case with individual shopfitting, because we don't just have straight cabinet compartments, but sometimes there's a recessed rear wall because there are installations above it, in the next compartment there's a sink cover, in the next compartment there's a cutout for a power socket. And I can always see where exactly this component is installed. That's an advantage that I personally wouldn't want to miss in our company.